|

WCB series of modular soil-cement mixing plant

WCB series of modular soil-cement mixing plant adopts industrial micro-computer control system, and has such advantages as even mixing, high productivity, multiple grading varieties, high modular degree,handy installation,debugging and maintenance,etc. It widely applies to foundation and base construction of all kinds of high-class roads and airport. Technical features:

- Adopting internationally fashionable modular design which is handy to install and speedy to change form.

- Double-horizontal-shaft forced mixing has strong mixing force and can realize rapid and even mixing.

- Steel plates of distributing plant adopt press-forming parts with strong rigidity and handsome shape.

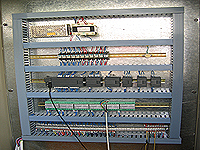

- Electric parts adopt complete set of quality imported parts of such international famous brand as SCHNEIDER,SIEMENSE,OMRON,etc. which have superior properties and are quite endurable. Automatic and manual operating modes are available and both flexible. Double operation of computer and control table are realized with much convenience and reliability.

- Abnormal working conditions and faults can be auto-detected and such indications as words,sound,light,and alarming are adopted to facilitate checking faults and removing them.

|

| Pictures: |

|

|

|

|

Finished material storage system adopts pneumatic opening system with big storage capacity and speedy unloading. |

Weighing sensor and computer control system form a closed-circuit control system which has strong anti-disturbance ability and can give separate, continuous,and single belt weighing to all kinds of aggregate. Discharging and weighing are conducted simultineously with accurate and steady weighing. |

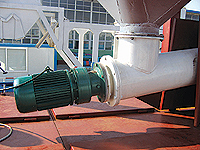

Speed control helical feeding machine,weighing helical,frequency changer,and computer control system form powder material distribution closed-loop control system to realize real-time monitoring and adjustment of powder material flow. This greatly reduces customers’ losses and improves finished material quality. |

|

|

|

|

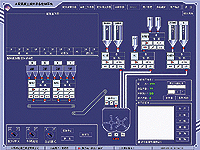

Upper unit of industrial control machine control mode has great management function, friendly customer interface and proper man-machine interactive function. |

Water flow remote-control system composed of target type flow meter and electric valve can set and regulate the water flow at the touch ot switch of control table. This saves operators’ labour from control room to main engine and has high control precision as well as short response time. |

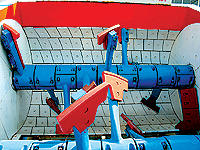

Double-horizontal-shaft forced with-no-lining technology widens the clearance between mixing blade and shell to the max. extent and reduces such faults as blade wearing, material chucking,and blade scuffing, etc. It frees you from frequent lining changes. |

|

|

|

|

Plant-mixing equipment |

Distributing system consists of aggregate container, weighing belt conveyor,and material belt collector.customers can have a free option of such special devices as distributing containers,flowing-aid breaker,etc. It has such advantages as compact structure,scientific layout,material container with large volume,material loading at a low height,high reliability,handy maintenance,etc. |

Finished materials well-mixed are delivered to corresponding containers through belt conveyor, which has a small inclination angle and quality seamless sulfurized joint ring shaped rubber tape with compact structure and can work smoothly with much reliability instead of running slantingly. This effectively improves belt’s using life. |

|

|

|

| Dalian reserves 360 |

Dalian Tong Yang HZS180 + HZS120 |

Electric 1 |

|

|

|

| Electric 2 |

Electrical schematic diagram |

Appliances |

|

|

|

| Powder delivery closed-loop control system |

Mixing part |

Control System |

|

|

|

| The spacious room for maintenance |

Langfang Zhongtai 120 |

pictrue 1 |

|

|

|

| Shenyang Sanyou 240 |

Stabilized Soil |

[Main technical parameters]

| Model |

WCB300 |

WCB400 |

WCB500 |

WCB600 |

Rated productivity

(t/h) |

300 |

400 |

500 |

600 |

Stone container volume

(m3) |

3×12 |

3×12 |

4×15 |

4×15 |

| Cement measuring container volume(m3) |

7 |

7 |

9 |

9 |

| Finished material container volume(m3) |

8 |

8 |

10 |

10 |

| Distributing precision |

Aggregate |

±3% |

±3% |

±3% |

±3% |

| Cement |

±1% |

±1% |

±1% |

±1% |

| Water |

±1% |

±1% |

±1% |

±1% |

| Aggregate grain size(mm) |

≤60 |

≤60 |

≤60 |

≤60 |

| Material loading height(m) |

3.9 |

3.9 |

4.2 |

4.2 |

| Material unloading height(m) |

3.1 |

3.1 |

3.1 |

3.1 |

| General power(kw) |

108 |

118 |

123 |

139 |

|